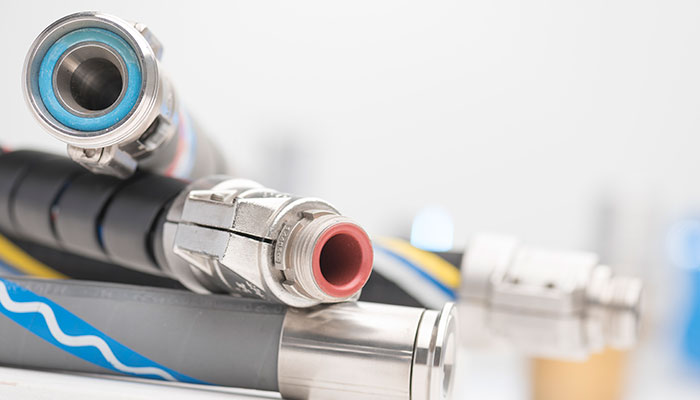

Valve fittings

The term “valve fittings” covers not only our reusable or crimp-fitted hose adapters, but also a whole range of coupling systems, clamps, strips, shutoff devices and tube bends.

They are available in brass, normal or stainless steel, or wrought copper alloys. Our state-of-the-art surface treatments conform to the latest technical standards, including the European RoHS Directive (2002/95/EC), and have been supplied with exclusively chrome (VI)-free passivation since 2007.

• Valve fittings

• Hose couplings

• Quick-action couplings

• Dry couplings

• Accessories

A secure connection at all times

Our business is concerned equally with the supply of original equipment and the delivery of drawing-based hose-conduit systems and spare parts. Our workshop makes and assembles pipe conduits for virtually all areas of application, from DN 2 right up to DN 300, along with their corresponding valve fittings.

FVarious attachment techniques are used with these valve fittings, depending on the type of hose conduit and its corresponding requirements. They can take the form of push-in adapters, quick-action couplings, reusable screw-in fittings, crimp connectors or valve fittings welded onto metal hoses.

Quality-control consists, depending on requirements, of leak and pressure testing carried out at up to 4,000 bar, followed by the corresponding, fully documented certification procedures.

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

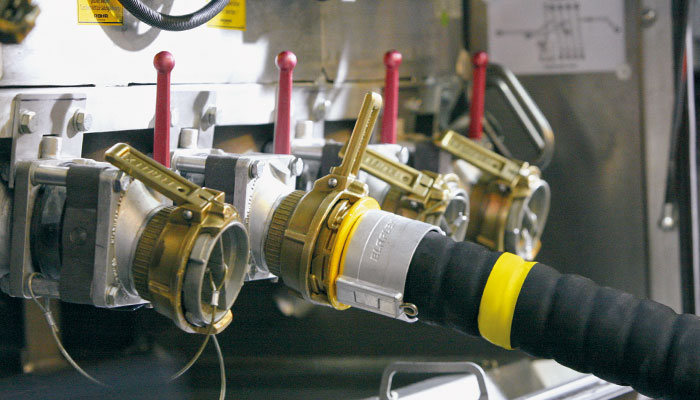

Oil / petroleum-product hoses

We can supply hoses for use with all types of oil and fuel products. The areas of application range from hydraulic systems to the loading and unloading of road tankers and fuel storage facilities. This is just a small selection from our overall range:

Lightweight road-tanker hose

Lightweight road-tanker hose

Lightweight, highly flexible suction/pressure hose for use with oil products. Complies with TRbF 131, part 2 at a nominal pressure of 10 bar.

Road-tanker hose type “D”

Road-tanker hose type “D”

Flexible pressure-hose for use with oil-based products with a maximum aromatic-compound content of 50%. Manufactured in accordance with EN 12115; fulfils TRbF 131, part 2, sect. 5.5.

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

Compressed-air hoses

Pneumatically actuated subassemblies and tools operate with a reliable compressed-air conveying system. VIGOT can supply you with compressed-air hoses that are thoroughly tried-and-tested in many fields and ready to meet any challenge. These are just some of the products in the range:

Compressor hose DIN 20018

Compressor hose DIN 20018

Robust, flexible, compressed-air hose made of rubber, designed for tough operating conditions. Equally suitable for freshwater, seawater and contaminated water.

TRIX® Blaustrahl / Blue Ray

TRIX® Blaustrahl / Blue Ray

Branded pressure hose for heavy-duty operation with compressed air. Conforms to EN ISO 2398. Highly flexible and robust. Good resistance to oil. Electrically conductive. Contains no LABS, stripping agents or grease.

Super Nobelair®

Super Nobelair®

Plastic compressed-air hose, flexible.

Super Nobelair® Soft

Super Nobelair® Soft

Plastic compressed-air hose, especially light and flexible. Ideal for supplying compressed air to pneumatic tools. TÜV-tested.

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

Gas hoses

Gas hoses need to meet the most-demanding of safety standards. The makes that we supply fulfil maximum quality specifications regarding robustness and correct functioning for use with gaseous and liquid substances. Examples of such products include:

Ammonia hose conforming to NF EN ISO 5771 (Dec. 1996)

Ammonia hose conforming to NF EN ISO 5771 (Dec. 1996)

For conveying water-free ammonia, in either liquid or gas form. Fulfils all the requirements of NF EN ISO 5771 (Dec. 1996). Available as a ready-assembled hose conduit with swaged couplings supplied to customer specifications. Other dimensions are available on request.

Oxyacetylene gas hose EN 559

Oxyacetylene gas hose EN 559

For the safe transport of oxygen and cutting/welding gases in conformity with DIN EN ISO 3821. Flexible and robust. Resistant to kinks and deformation. Contains no LABS, stripping agents or grease.

TRIX® all-round cutting/welding gas hose

TRIX® all-round cutting/welding gas hose

Designed for conveying all cutting/welding gases and liquid gases conforming to DIN 51622, along with propane/butane, natural gas, DMF, MPS and LPG. Conforming to DIN EN ISO 3821, it is extremely robust, flexible and resistant to ageing and the weather, while offering a smooth, dirt-resistant surface structure. Resistant to kinks and deformation, contains no LABS, stripping agents or grease.

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

Water hoses

The water hoses in our catalogue fulfil a complete range of industrial and commercial application requirements. When it comes to the transport of drinking water, we offer a selection of products designed to meet all the demands of consumers and authorities alike. Here are a few examples:

Aquapal®

Aquapal®

Highly flexible drinking-water hose, absolutely odour- and taste-neutral. Authorised in accordance with the KTW “pipes and tubes” directive, DVGW-W270 and DVGW-VP549, FDA-compliant.

Cristal

Cristal

Soft, crystal-clear PVC hose designed for use with non-pressurised liquids.

Primabel®

Primabel®

Flexible, multi-layer PVC water hose with honeycomb-shaped Soft&Flex structure.

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

Für schwierigste Einsatzbedingungen

Zum Schutz in Produktionen mit hohen Temperaturen

Hütten, Glasereien und andere Branchen, in denen bei hohen Temperaturen produziert wird, benötigen für die technischen Schläuche einen besonderen Schutz und besondere Ausführungen. Durch die hohen Umgebungstemperaturen müssen die Schläuche beim Kühlen z. B. von Elektro-Hochstromkabel besondere Voraussetzungen erfüllen. Die Schlauchpalette von VIGOT unterstützt diesen Industriezweig und liefert ein hervorragendes Sortiment an Kühlschläuchen für die unterschiedlichsten Anwendungsbereiche.

Kühlwasserschläuche im Einsatz:

Kühlwassersysteme, stationäre Aggregate, Kühler- und Heizungssysteme, Hochofen, Ofenanlage, Hochstromseile, Stahlwerke, Glashütten, elektrische Öfen, Induktionsherde, Gießereien, Lichtbogenöfen, Kondensatoren, Umrichter, Stranggussanlagen (Gießbogen), Warmwalzwerke.

Kühlwasserschlauch Maximall E - CR

Findet als Kühlwasserschlauch Einsatz in einer Vielzahl unterschiedlicher Öfen, zum Beispiel Induktionsöfen, Lichtbogenöfen, Pfannenöfen, Warmhalteöfen, Mittelfrequenzöfen. Weitere Gebiete sind wassergekühlte Hochstromkabel und Induktionsspulen. Die Decke ist selbstverlöschend nach ASTM G-542.

Findet als Kühlwasserschlauch Einsatz in einer Vielzahl unterschiedlicher Öfen, zum Beispiel Induktionsöfen, Lichtbogenöfen, Pfannenöfen, Warmhalteöfen, Mittelfrequenzöfen. Weitere Gebiete sind wassergekühlte Hochstromkabel und Induktionsspulen. Die Decke ist selbstverlöschend nach ASTM G-542.

Weitere Informationen finden Sie unter Downloads.

Kühlwasserschlauch Maximall E

Blaue Decke (EPDM), elektrisch isolierend. Seele schwarz (EPDM Gummi), geeignet für Heißwasser, Prozesswasser, Frostschutz und Antikorrosionsmittel. Hält Temperaturen zwischen -30 °C und +90 °C stand, kurzzeitig auch 110 °C. Einsatzbereiche sind zum Beispiel Schaltschränke, wassergekühlte Hochstromkabel, Thyristoren, Elektroöfen und Induktionsspulen.

Blaue Decke (EPDM), elektrisch isolierend. Seele schwarz (EPDM Gummi), geeignet für Heißwasser, Prozesswasser, Frostschutz und Antikorrosionsmittel. Hält Temperaturen zwischen -30 °C und +90 °C stand, kurzzeitig auch 110 °C. Einsatzbereiche sind zum Beispiel Schaltschränke, wassergekühlte Hochstromkabel, Thyristoren, Elektroöfen und Induktionsspulen.

Weitere Informationen finden Sie unter Downloads.

Hochofenschlauch HKWS

Der Kühlwasserschlauch verrät schon im Namen seinen Einsatzbereich. In schwerer Ausführung mit 3-fachem Stahldrahtgeflecht, eignet er sich für den Hochofenbereich, Stranggussanlagen (Gießbogen), Warmwalzwerke, u.v.m. Die Einbindung der Armaturen erfolgt mit Messing- oder Edelstahl-Klemmschalen. Der Temperaturbereich reicht bis +120°C und der Berstdruck liegt bei 60 bar.

Der Kühlwasserschlauch verrät schon im Namen seinen Einsatzbereich. In schwerer Ausführung mit 3-fachem Stahldrahtgeflecht, eignet er sich für den Hochofenbereich, Stranggussanlagen (Gießbogen), Warmwalzwerke, u.v.m. Die Einbindung der Armaturen erfolgt mit Messing- oder Edelstahl-Klemmschalen. Der Temperaturbereich reicht bis +120°C und der Berstdruck liegt bei 60 bar.

Kühlwasserschlauch non-conductive

Die wesentlichste Eigenschaft des Kühlwasserschlauches ist sein nicht-leitender Charakter. Der Silikonschlauch hat eine rote Silikonseele und eine blaue Außendecke, elektrisch nicht leitend

Die wesentlichste Eigenschaft des Kühlwasserschlauches ist sein nicht-leitender Charakter. Der Silikonschlauch hat eine rote Silikonseele und eine blaue Außendecke, elektrisch nicht leitend

R >10 Ω/m und mit einer Durchschlagfestigkeit von > 6kv /mm, Norm ASTM D149. Er findet Einsatz in Induktionsanlagen, Kondensatoren, Umrichter u.v.m. Er eignet sich außerdem für Kühl- und Prozesswasser bis 100°C sowie Pressluft.

Gelenkbolzenschellen

Die passenden Gelenkbolzschellen für die Kühlwasserschläuche, gefertigt aus W4 = 1.4301 (ein Stahl der gegen Wasser, Wasserdampf, Luftfeuchtigkeit, Speisesäuren sowie schwache organische und anorganische Säuren beständig ist) und W5 = 1.4571. Die erhöhte Beständigkeit dieses Materials gegen Korrosion und Lochfraß ist u.a. prädestiniert für den Einsatz auf dem weiten Gebiet des chemischen Apparatebaus.

Die passenden Gelenkbolzschellen für die Kühlwasserschläuche, gefertigt aus W4 = 1.4301 (ein Stahl der gegen Wasser, Wasserdampf, Luftfeuchtigkeit, Speisesäuren sowie schwache organische und anorganische Säuren beständig ist) und W5 = 1.4571. Die erhöhte Beständigkeit dieses Materials gegen Korrosion und Lochfraß ist u.a. prädestiniert für den Einsatz auf dem weiten Gebiet des chemischen Apparatebaus.

Sicherheitsschellen Bronze antimagnetisch

Die Sicherheitsschellen aus Bronze verkörpern ein Produkt, das stromleitfähig und antimagnetisch ist. Die Schellen ermöglichen den gleichzeitigen Einsatz als Klemme und Leiter und decken somit auch elektrotechnische Zwecke ab, wobei weitere Bauteile an der Einstelle entfallen können.

Die Sicherheitsschellen aus Bronze verkörpern ein Produkt, das stromleitfähig und antimagnetisch ist. Die Schellen ermöglichen den gleichzeitigen Einsatz als Klemme und Leiter und decken somit auch elektrotechnische Zwecke ab, wobei weitere Bauteile an der Einstelle entfallen können.

Hochtemperaturschläuche

Höchste Zuverlässigkeit auch bei extremen Temperaturen

Je nach dem, welche individuellen Eigenschaften im Hochtemperatureinsatz gefragt sind, finden Sie bei VIGOT eine große Auswahl an maßgeschneiderten Lösungen. Hier eine kleine Auswahl aus dem aktuellen Sortiment:

Je nach dem, welche individuellen Eigenschaften im Hochtemperatureinsatz gefragt sind, finden Sie bei VIGOT eine große Auswahl an maßgeschneiderten Lösungen. Hier eine kleine Auswahl aus dem aktuellen Sortiment:

Flexadux® Hypalon T CL

Flexadux® Hypalon T CL

Hochflexibler zweilagiger Spiralschlauch, innen Teflon-Folie, außen Hypalon-beschichtetes Polyestergewebe, außen schwarz, innen weiß. Sehr gute Chemikalienbeständigkeit, witterungsbeständig, außenliegende Scheuerschutzspirale, gute Stauchbarkeit, schwer entflammbar, vibrationsfest, sehr gute UV- und Ozonbeständigkeit.

Flexadux® Teflon® CL

Flexadux® Teflon® CL

Sehr leichter und hochflexibler Spiralschlauch aus PTFE-beschichtetem Glasgewebe, braun. Sehr gute Chemikalienbeständigkeit, gute Temperaturbeständigkeit, außenliegende Scheuerschutzspirale, gute Stauchbarkeit.

Silikon-Heißluftschlauch, einlagig

Silikon-Heißluftschlauch, einlagig

Heißluftschlauch aus Silikon-beschichtetem Glasfasergewebe, einlagig, rotbraun. Sehr gut hitzebeständig, gute Kälteflexibilität, gute chemische Beständigkeit.

Mehr Infos zu dieser Produktgruppe finden Sie in unserem Katalog „Schlauchtechnik – Safety first“. Ein Klick auf den Button führt Sie automatisch zur entsprechenden Seite.

Ready-made steam hoses for industrial use

Steam and hot water for cleaning and sterilisation

Steam is used as an energy transmission medium and for sterilisation and cleaning in a wide variety of industrial applications, for example in the food industry where the highest hygiene standards have to be met. Using saturated steam is especially popular. It has a high thermal transfer coefficient and permits precise temperature adjustment by controlling the pressure. Tough dirt can be removed even from narrow gaps and bacteria are neutralised. Safely transporting steam from the generator to the place of use, even over longer distances, is essential so your company can benefit from these useful characteristics. Materials that stand up to high pressure and heat are needed here: you will find them in steam and hot water hoses of high quality. Such hoses also permit the precise application of steam, for example when cleaning surfaces. They are suitable to heat tank cars or for the controlled heating and moistening of products as well.

Our hose selection includes electrically conductive, oil-resistant hoses. They are suitable for the transportation of steam and hot water in the following fields of application among others:

• Chemical and petrochemical industry

• Food industry

• Cosmetics industry

• Building trade

• Refineries

• Shipping

• Horticulture operations

PERLAPAL®-W:

PERLAPAL®-W:

NBR cover and CIIR inner tube, resistant to hot water up to 95°C and steam up to 164°C

Dairy steam hose:

Dairy steam hose:

synthetic rubber cover and EPDM inner tube, resistant to hot water up to 95°C and steam up to 164°C

For maximum transport safety: steam and hot water hoses

Steam hoses have to meet the highest safety standards because steam has tremendous force: one litre of water corresponds to 1,700 litres of steam. That is why hoses for transporting this medium are produced according to the highest quality standards. EPDM is commonly used for the cover and inner tube. It is highly resistant to chemicals and heat, with good elasticity and electrical insulation strength. Since steam hoses are commonly used in the food industry, they also have to be resistant to animal and plant fats.

The EN ISO 6134 standard was developed to guarantee consistent safety standards across Germany for hoses to transport saturated steam. VIGOT Industrietechnik GmbH offers steam hoses produced according to this standard:

Dampf TRIX® 5000:

Dampf TRIX® 5000:

saturated steam up to 6 bar and hot water up to 120°C, lining made of temperature and hydrolysis-resistant aramid, resistant to UV radiation, weathering and ozone

Dampf TRIX® 6000:

Dampf TRIX® 6000:

saturated steam up to 18 bar, optimised against popcorning, lining made of double steel mesh, resistant to UV radiation, weathering and ozone

Dampf-TRIX® 6000 Oil:

Dampf-TRIX® 6000 Oil:

saturated steam up to 18 bar, exterior resistant to oil, optimised against popcorning

PYROPAL® 230:

PYROPAL® 230:

saturated steam up to 18 bar, lining made of two layers of asymmetrically woven, corrosion protected steel mesh

All hoses are supplied fully assembled with the appropriate fittings. Naturally all hoses are DIN EN 10204 certified.

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

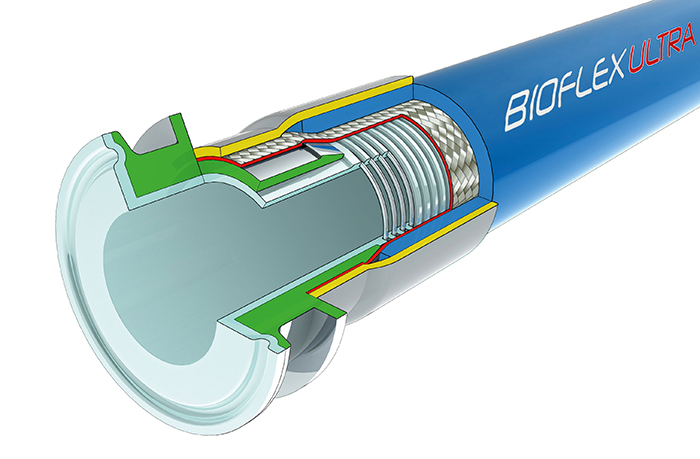

Chemical hoses and pharmaceutical hoses

A safe connection for optimum coating and maximum load-bearing capacity

Safety is our highest principle for every hose line, in every industry. In industry, acids, alkalis, salt solutions and other highly reactive liquids are often transported. To prevent these from attacking and decomposing the chemical or pharmaceutical hose, it must be as inert as possible. For more than seventy years, PTFE, one of the least reactive materials of all, has proven itself as a coating material for the chemical hose. The broadly diversified portfolio of VIGOT Industrietechnik GmbH includes both durable PTFE and silicone hoses.

Apart from chemical stability, the mechanical and thermal load capacity is also of fundamental importance for every hose line. VIGOT Industrietechnik GmbH offers different products, which differ with regard to the maximum or minimum pressure load. Pharmaceutical hoses can be used for suction and also for pressure applications. Depending on the respective location of use, the minimum bending radius of the PTFE hose is also important, as not all products are suitable for particularly tight curves.

Another important property of PTFE hoses used in the chemical and pharmaceutical industry is their thermal resistance. Frequently, substances must be transported at temperatures of more than 200 °C. In a potentially explosive environment, a flame-retardant and electrically conductive chemical or pharmaceutical hose is used. These so-called "Ohm/T" hoses are also available in different versions, if required also with antistatic equipment.

In addition, especially in the pharmaceutical and chemical industries, the sterility of the hose is a fundamental requirement for its use. A large number of the hose assemblies of VIGOT Industrietechnik GmbH can be heated to more than 100 °C for a limited time in order to clean and sterilize them thoroughly with steam.

All hoses are supplied fully assembled with the appropriate fittings. Of course, all hoses are provided with a certificate according to DIN EN 10204. You can find more information about this product group in our catalogue "Hose Technology - Safety first".

All hoses are supplied fully assembled with the appropriate fittings. Of course, all hoses are provided with a certificate according to DIN EN 10204. You can find more information about this product group in our catalogue "Hose Technology - Safety first".

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

A safe connection - Hoses for use in the chemical and pharmaceutical sectors

ELAFLEX – with a tradition of strength

Safety is the top priority in the chemicals industry. ELAFLEX manufactures hoses designed to carry chemical products, fuels and other liquid substances. These hoses, which fulfil even the most-demanding safety requirements, are characterised by their long service life and flexibility.

High-quality valve fittings complete our range. These valve fittings, which conform to the corresponding standards, are designed for a long, hard working life. The uncompromising ELAFLEX approach to quality also ensures maximum operating reliability.

Developed for use with highly pure substances in a wide range of applications

TECNO PLAST – the flexible-coupling specialist

Our partner TECNO PLAST focuses its efforts on the highly specific requirements of the pharmaceutical, chemical and biotechnology sectors. Its range of PTFE and silicon hoses, which has been developed with these sectors in mind, fulfils all the relevant specification parameters of hoses designed to handle highly pure substances. The range of applications includes use with – above all – sterile products, pharmaceuticals, biotechnology, foodstuff-related items and chemicals; and wherever ease of cleaning is a priority.

These couplings are complemented by a range of sterile valve-fittings. An intermediate space optimises the transitions between hose and valve fitting.

Please refer to our catalogue entitled “Hose technology– Safety first” for further details of this group of products. Just click on the button to go straight to the corresponding page.

Fire-sleeves:

Safety first

VIGOT fire-sleeves are made of a specially impregnated, mineral-based carrier material. This heat protection fabric presents no health risk and fulfils the requirements of the health regulations to a high degree.

www.fire-sleeve-f88.com

Our portfolio online

You can also find a section from the whole range of our products on the Internet. This link takes you to our new e-catalogue. Here our customers will find all the useful information about our products and can also use our request module to upload all the details for a customised quotation. Go to the e-catalogue

SCHAUENBURG Industrietechnik

As a system supplier, we are a reliable partner to industry for technically convincing product solutions. One Stop Solution is the principle after we accompany projects from development to series production in many important industries. In doing so, we operate successfully on the national and international market. Read more...