Hose testing: test center and mobile on site

SCHAUENBURG Industrietechnik with the VIGOT® brand has made safety its top priority - "Safety first". This includes professionally qualified training in accordance with "Qualified person according to Betr.SichV §2 para. 7 or TRBS 1203". Regular inspections, supported by maintenance contracts, are a prerequisite for the use of hose lines in machinery and contribute to the safety of man and machine, thus minimizing downtimes. The periodic inspections take place on site.

SCHAUENBURG Industrietechnik with the VIGOT® brand has made safety its top priority - "Safety first". This includes professionally qualified training in accordance with "Qualified person according to Betr.SichV §2 para. 7 or TRBS 1203". Regular inspections, supported by maintenance contracts, are a prerequisite for the use of hose lines in machinery and contribute to the safety of man and machine, thus minimizing downtimes. The periodic inspections take place on site.

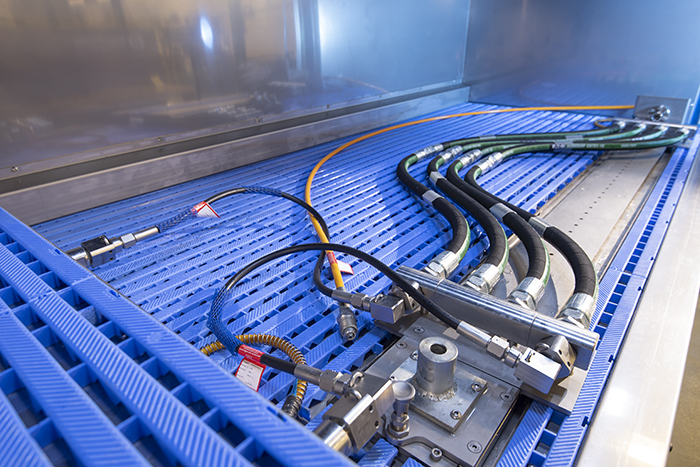

Test center for hose lines

Test center for hose lines

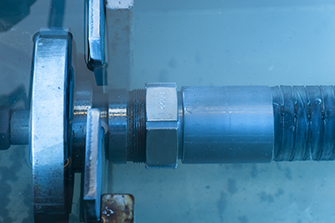

Hose lines that are assembled by us are then inspected in our in-house test center. Here, the hoses are tested in accordance with the requirements at up to 4000 bar. We have an underwater test stand, which is essential for metal hose lines. Our test center offers all the necessary testing options, from underwater leak tests to strength tests up to 4000 bar. The hose lines receive a product passport that accompanies them for the entire service life of the hose and provides transparent documentation for your machinery and employees.

• First-class equipped test center

• First-class equipped test center

• Test pressure certificates up to 4000 bar

• Leak tests with air under water

• Unmistakable marking of the products

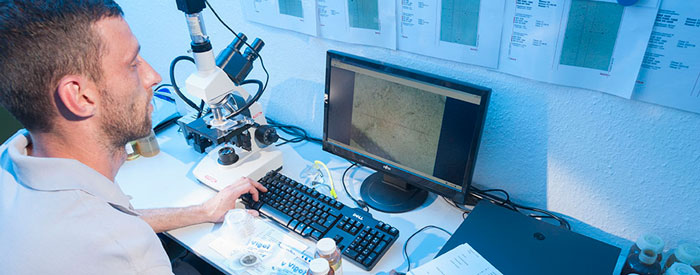

• Endoscopy and analyses

• Very high testing capacity

Mobile hose testing on site

Mobile hose testing on site

Our on-site testing service, carried out by our specialists, significantly reduces machine downtimes and helps you to fulfill legal obligations smoothly. Regular inspections of your hose lines are prescribed by the manufacturer. For chemical, food, metal and steam hose systems, repeat inspections at fixed intervals similar to a TÜV inspection are mandatory. SCHAUENBURG Industrietechnik specializes in mobile testing and has the know-how, the equipment and, above all, hose specialists with all the necessary approvals and extensive experience!![]()

• Compliance with legal regulations

• Replacement of defective hose lines

• On-site installation service

• Testing at your factory

• Minimization of downtimes

• Advice on hoses and their use

Our additional service: The hose register

Hose lines are recorded in a hose register. This allows you to see historically when which hose was tested. The chronological sequence and lists for upcoming inspections are important components of a smooth and fast inspection. Our service enables you to plan optimally.

With our testing service, you fulfill your responsibilities in the best possible way and make a significant contribution to protecting employees and the environment. Tested and functional hose lines are crucial for the long-term economic operation of your systems.

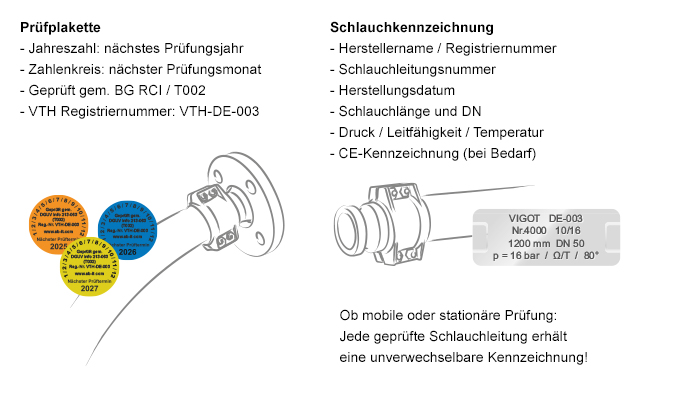

How to recognize a tested hose line

How to recognize a tested hose line

Assembler of hose lines

VIGOT® always a secure connection

SCHAUENBURG Industrietechnik, under the VIGOT® brand, is one of the leading manufacturers and assemblers of ready-to-install hose lines in Germany.

The documented quality of the work is demonstrated by certified specialist personnel with optimum training. ISO 9001 certification and continuous monitoring ensure first-class results in the long term.

Stock goods · Cutting lengths · Roller burnishing

Work preparation · Pressing · Test bench

VIGOT® is an OEM partner

The field of activity includes both the provision of original equipment and the supply of customized hose lines according to technical drawings as well as replacement hose lines. Our production facilities manufacture and assemble hose lines for a wide range of applications, with diameters from DN 2 to DN 300 and corresponding fittings.

Our in-house workshops are professionally and modernly equipped. The assembled hose lines are produced at several locations in Germany. High-quality testing facilities at the production sites ensure the outstanding certified safety of the hose lines. Production for sensitive areas such as the food, chemical and pharmaceutical industries is handled, as is the supply of hydraulic hoses and water hoses.

The package is completed by a selection of hose reels, from stainless steel for hygienic areas to reels for compressed air in confined spaces with our special VIGOT® type A model.

Integration of hose lines · Quality control

Integration of hose lines · Quality control

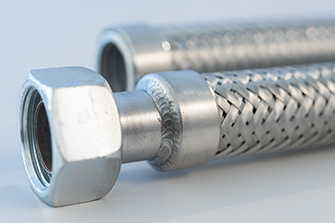

Various connection techniques are available for mounting the fittings on the hose lines, depending on the specific requirements. These include plug-in connections, clamp fastenings, reusable screw fittings, crimp connections and welded fittings on metal hoses.

Crimping hose lines

Bound hose line · Welded hose line

Bound hose line · Welded hose line

Ultra Clean

Cleaning hoses with the "Ultra Clean Launcher"

We use the Ultra Clean Launcher to clean hoses, pipes and lines. The launcher removes the dirt from the hose by shooting cleaning projectiles through it. These projectiles have an internal diameter 20-30% larger than the hoses that need to be cleaned. The slightly larger diameter pushes the unwanted particles out of the hose. With our range of different projectiles and mouthpieces, we can adjust the launcher to different areas of application.

This product from Ultra Clean Technologies Corp. can be purchased from us. We also offer the cleaning of your hoses, pipes or lines with the Ultra Clean Launcher. Contact us to make an appointment with one of our competent employees!

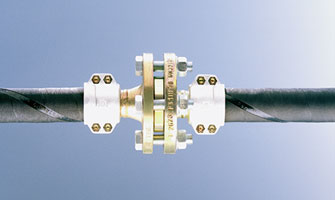

"Ultra Clean Seal" - sealing capsule for hoses

The "Ultra Clean Seal" sealing capsule provides a permanent seal for hoses. By applying heat, the end capsule is precisely adapted to the end of the hose and seals the hose securely. The capsules are easy to remove.

This product from Ultra Clean Technologies Corp. is available from us. Contact us for advice and further information!

"Ultra Clean Seal" - flange seal

The "Ultra Clean Seal" flange seal offers a safe and clean solution for sealing flanges. It prevents dirt from entering the hose and liquids such as oil from escaping. The closure is easy to install and requires no additional tools.

This product from Ultra Clean Technologies Corp. is available from us. Contact us for a consultation, we are at your service!

Component management

Modular solutions

As a service provider, we consider it our mission to provide the best-possible all-round service to you as your partner and supplier. This includes our component-management service.

As a single-source supplier, we contribute to reducing costs, while allowing you, our valued customer, to concentrate on your own core areas of competence. Joint long-term partnerships in this respect help to ensure smooth-running procedures. You can alternatively use our modular system, which allows you to select a suitable element from our range to meet your needs.

· Procurement

· Logistics

· B2B relationships

· Multiple-container systems

· Kanban

· Storage

· Individual concepts

Oil service and analysis

As a partner of HYDAC-Öl-Service, we offer you a systematically structured service program that makes a significant contribution to extending the operating times of hydraulic systems, lubrication systems and electrohydraulic control and regulation systems through proper maintenance and inspection.

Regular inspection of operating and system parameters prevents expensive downtime. As a partner of the HYDAC Service Center, we check the oil and filter condition, for instance.

Oil analysis

Our Hydac oil service includes a structured and comprehensive service program aimed at extending operating times.

Types of contamination and oil analysis

Oil contamination can occur in various ways. Regular monitoring is necessary to prevent damage as far as possible.

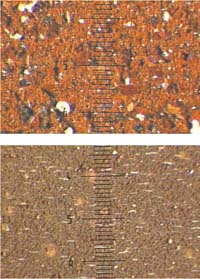

This graphic example explains two types of contamination: (1 line division = 45 ym)

Upper image

Upper image

ype of particle: mainly rust; white particles: additives

Effects

· Pronounced ageing of oil

· Malfunctioning pumps and valves

· Wear, due mainly to water in oil

Lower image

Type of particle: products resulting from ageing of oil

Effects

· Filter blockages

· Accumulations of sludge in system

Timely intervention can save you considerable costs.

Just contact us!

Guide to contamination

Guide to contamination

Familiarise yourself with the basic principles of oil contamination. The enclosed guide contains initial information and examples![]() PDF Guide to contamination

PDF Guide to contamination

Engineering services for innovative solutions

SCHAUENBURG Industrietechnik supports its customers with the VIGOT® brand in hose technology through special services and, in particular, individual developments. Our aim is to develop and implement smooth processes for our customers by supplying modular systems that enable flexible and customized integration of hose lines into their products. For OEM customers in particular, we develop systems that optimize this workflow.

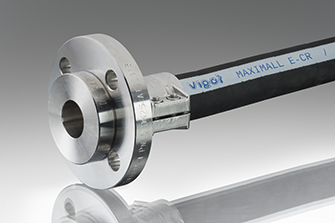

Innovative solutions for hose technology such as the MAXIMALL S 2000, the fire protection hose type F88 and support rails are naturally part of our portfolio. We have been carrying out these developments in accordance with market and demand requirements for more than 50 years.

The second major field of activity is services relating to hose lines. This includes mobile hose testing with a test range of 2 to 500 bar in mobile use and up to 4,000 bar in our in-house test center, including underwater testing and on-site oil analysis.

Our trained team is of course available for your inquiries.

VIGOT® marine hose

VIGOT® marine hose

MAXIMALL® S 2000-type

Hose-conduit system for use in marine engineering, with GL and BAAINBw permits

VIGOT® fire-sleeve

VIGOT® fire-sleeve

Type F 88

VIGOT® fire-sleeves are the culmination of many years’ experience in the manufacture of insulating materials for use in fire prevention.

VIGOT® reel systems

VIGOT® reel systems

Type A

VIGOT® hose and cable reels have been helping to improve industrial health and safety for more than 50 years

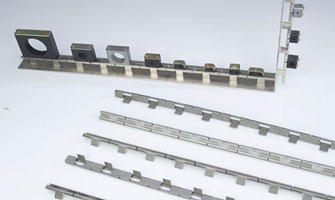

VIGOT® support rail

VIGOT® support rail

Type VMC

The VMC system permits the flexible configuration of clamp-types conforming to DIN 3015

Customized solutions in hose technology

The expertise of VIGOT®, a brand of SCHAUENBURG Industrietechnik, is based on years of experience and customized advice for our customers, even in complex situations. With our teams spread across various locations in Germany, we pool engineering resources to meet the challenges of the market.

This cooperative collaboration in our diverse teams leads to market-driven and technologically refined products that are convincing in terms of economy, ecology and safety. The development expertise that has driven the VIGOT® brand for more than 160 years is a convincing cornerstone of this collaboration. Products such as the MAXIMALL® range are a guarantee of quality and innovation.

SCHAUENBURG Industrietechnik also offers development services for products in our area of expertise. The production of special designs according to individual customer requirements formed the basis for the development of our own systems at VIGOT®. In the following we present some of our current in-house developments.

Fire-sleeves:

Safety first

VIGOT fire-sleeves are made of a specially impregnated, mineral-based carrier material. This heat protection fabric presents no health risk and fulfils the requirements of the health regulations to a high degree.

www.fire-sleeve-f88.com

Our portfolio online

You can also find a section from the whole range of our products on the Internet. This link takes you to our new e-catalogue. Here our customers will find all the useful information about our products and can also use our request module to upload all the details for a customised quotation. Go to the e-catalogue

SCHAUENBURG Industrietechnik

As a system supplier, we are a reliable partner to industry for technically convincing product solutions. One Stop Solution is the principle after we accompany projects from development to series production in many important industries. In doing so, we operate successfully on the national and international market. Read more...