Valve fittings for every requirement

VIGOT® supplies both a selection of standard valve fittings for hose conduits and individually-made items designed to meet special requirements. The VIGOT® Company’s own in-house turning and welding shops make and modify the required valve fittings to customer specifications. These facilities can handle all metallic materials, such as normal and stainless steel, brass, aluminium, or wrought copper alloys; along with matching surface treatments.

See below for selected details of our standard range. Other valve fittings and specially made items can be obtained on request.

Hoses for food-and-beverage use, the chemicals sector and industry in general

Swaged and flange fittings in normal and stainless steel, brass or aluminium, with features such as screw-in milking tube adapters, flanged couplings, threaded couplings, Camlock couplings, Storz couplings, steam valves

Hydraulic hoses

Hose fittings conforming to DIN ISO 12151, e.g. conical nipples with O-ring (light and heavy), threaded stems with 24° and 60° borings, flanged connections with O-ring for flange conforming to ISO 6162 (3000 and 6000 PSI), JIC, NPT and BSP threaded couplings, hoses made up using swaged, threaded and push-in fittings made of normal or stainless steel

Metal hoses

Hose fittings conforming to DIN 2999, flanged couplings conforming to DIN and ISO, screw-in milking tubes adapters conforming to DIN 11851, made off malleable cast iron, gunmetal, brass, normal and stainless steel

Water/compressed-air hoses

Connection adapters for water, Geka and compressed-air couplings, sleeve-type and push-in couplings made of brass or malleable cast iron

Tank-filling hoses

SQuick-action couplings made of stainless steel, brass, normal steel or aluminium, e.g. road-tanker, Storz-type, lever-arm or Perrot couplings

Tube fittings

Components conforming to DIN 2353 / DIN EN ISO 8434-1, made of normal and stainless steel; special materials possible

Peripherals

Ranging from simple clamps to inspection windows or metering screw connections, clamps conforming to DIN 3015 or filters. Special technology available if desired

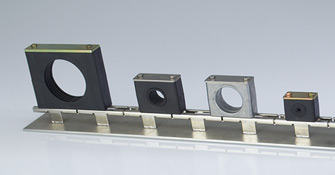

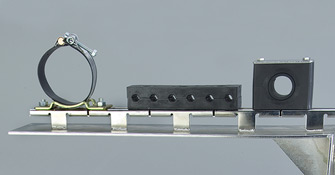

VMC-type support rail

The VMC support rail is designed for the flexible installation of hydraulic and pneumatic hose conduits, pipes, cables and cable troughs, along with sprinkler systems. Our specially developed fixing technology and geometry keep your installation flexible, while delivering considerable cost savings.

The VMC support rail is designed for the flexible installation of hydraulic and pneumatic hose conduits, pipes, cables and cable troughs, along with sprinkler systems. Our specially developed fixing technology and geometry keep your installation flexible, while delivering considerable cost savings.

Our specially developed fixing technology permits the flexible installation of:

· Hydraulic and pneumatic hose conduits

· Pipes

· Cables and cable troughs

· Sprinkler systems

Our specially developed fixing technology and geometry keep your installation flexible, while delivering considerable cost savings:

· Less need for welding during installation

· Space-saving installation configurations

· Angled installations

· Bridging of weld seams and surface imperfections

· Weight reduction

The VMC support-rail system permits the flexible configuration of the following clamp types conforming to DIN 3015:

· All clamps in our lightweight range (for pipe diameters from 6 mm to 101.6 mm)

· Twin, all-rubber clamps for pipe diameters from 6 mm to 20 mm

· Elastomer inserts for pipe diameters from 6 mm to 32 mm

· All-rubber clamps

· Aluminium clamps

Products and manufacturing competence

Our catalogue includes moulded components made of rubber and plastic, designed for use in various industrial applications; along with a range of profile-technology products that has grown steadily over the decades. This includes everything from hoses for simple industrial uses to hydraulic hoses, chemical hoses and special hoses requiring corresponding approval. Further highlights of the range include profile-technology products and stamped components made of rubber and high-performance plastics. Individual solutions consisting of special components and customised subassemblies round off our comprehensive range of industrial items.

Our catalogue includes moulded components made of rubber and plastic, designed for use in various industrial applications; along with a range of profile-technology products that has grown steadily over the decades. This includes everything from hoses for simple industrial uses to hydraulic hoses, chemical hoses and special hoses requiring corresponding approval. Further highlights of the range include profile-technology products and stamped components made of rubber and high-performance plastics. Individual solutions consisting of special components and customised subassemblies round off our comprehensive range of industrial items.

Cable and hose reels

Die optimale Handhabung von unterschiedlichen Medien wie Wasser, Öl, Luft, chemische Produkte und Produkte aus dem Lebensmittelbereich ist unser Spezialgebiet. Im Bereich der Aufrolltechnik stellen wir Schlauchaufroller für Industrie und Gewerbe her mit einer maximalen Aufroll-Länge bis 40 Meter bei DN 32.

Wir haben Kabelaufroller mit und ohne Schleifringe im Programm, bei einer Aufrollänge bis zu 50 Metern. Installationssäulen kombinieren wir mit Schlauch- und/ oder Kabelaufrollern. Ergänzt wird unser Portfolio mit Balancer, Schwenkarmen und Energiegondeln. Bei der Produktion unserer Kabel- und Schlauchaufroller hat die Qualität bei der Materialauswahl oberste Priorität. Die Anfertigung von Sonderausführungen nach Ihren individuellen Wünschen für einen optimalen Einsatz in Ihrem Betrieb ist für uns eine Selbstverständlichkeit. Dabei verwenden wir für besondere Anforderungen auch spezielle Materialien wie z.B. Edelstahl.

Unsere Aufrollsysteme für Kabel und Schläuche garantieren nicht nur einen sicheren Transport für unterschiedlichste Medien in einer Vielzahl von Branchen. Die Schlauchaufroller bewähren sich außerdem bei der ergonomischen Einrichtung von Maschinen, Geräten und Anlagen. Dadurch erhöht sich die Effizienz am Arbeitsplatz. Auch für ein sicheres und sauberes Arbeiten ist Ordnung im Kabelmanagement wichtig, Stolperfallen und Verwechslungsrisiken werden reduziert. Arretierung und Zugentlastung in jedem System sorgen für Zugentlastung und einfaches Aufrollen. Unserer Schlauchaufroller sind sehr langlebig, wir bieten Zubehör und auch Ersatzteile von Rasterhebel über Rasterschraube, bis zu den Schläuchen für die Aufroller an.

Schlauchaufroller BT 3000

Schlauchaufroller BT 3000

Die flexible Verbindung von der Festleitung zum Werkzeug mit Federrückzug und abschaltbarer Arretierung. Eine robuste Konstruktion für die starre, schwenk- oder drehbare Montage an der Wand oder Decke. Geeignet für Druckluft, Öl, Wasser oder Fett. Betriebsdruck bis max. 20 bar, für Schlauchlängen von 8 m bis 20 m.

Schlauchaufroller BT 4000-Duo

Schlauchaufroller BT 4000-Duo

Langlebig und robust, die sichere Verbindung von Luft- und Sprühmedium für den Einsatz in der Farbspritztechnik. Sichere Arretierung durch Rückholfeder aus Qualitätsstahl. Die Befestigung des geschlossenen Abrollsystems erfolgt an Wand, Decke oder Boden. Für Schlauchlängen von 10 m bis 15 m.

Schlauchaufroller BT 4000

Schlauchaufroller BT 4000

Für eine sichere Verbindung von der Druckluft-Festleitung zum Werkzeug. Öl- und benzinresistenter PVC-Schlauch mit optimalem Luftdurchgang und abschaltbarer Arretierung. Für Wand-, Decken- und Bodenmontage geeignet. Langlebige Rückholfeder aus Spezial-Federstahl. Schlauchlängen von 2 m bis 20 m.

Schlauchaufroller BT 5000

Schlauchaufroller BT 5000

Automatisches Schlauchsystem für Decken- Wand- und Bodenmontage mit Federrückzug. Vielseitige Verbindung von der Festleitung zum Anwendungsort oder Werkzeug für Öl, Wasser und Druckluft mit großem Mediendurchgang. Geeignet für Garagen, Waschanlagen, Küchen und Industrie, mögliche Schlauchlängen von 10 m bis 30 m.

Schlauchaufroller BT 6000

Schlauchaufroller BT 6000

Aus der Praxis für die Praxis: robuste Metallkonstruktion für die Verbindung von der Festleitung zum Anwendungsort oder Werkzeug. Öl-, wasser- und druckluftgeeignet bei einer Schlauchlänge von 20 m bis 50 m. Montagemöglichkeit an der Wand oder am Boden. Einsatzbereit in Garagen, Waschanlagen, Küchen und in der Industrie.

Schlauchaufroller BT 7000

Schlauchaufroller BT 7000

Spezialsystem mit Doppelschlauch NW 6/9, gefertigt nach DIN 8541/1/EN für die Verbindung vom festen Standort zum Anwendungsort. Für Acetylen und Sauerstoff. Achse und Drehkörper aus Messing, die Oberflächen sind kunststoffbeschichtet. Arretierung mit 2 Einrastmöglichkeiten pro Umdrehung.

Edelstahl-Schlauchaufroller VA 5000

Edelstahl-Schlauchaufroller VA 5000

Für den Einsatz in Betrieben mit höchsten Hygieneansprüchen wie Krankenhäuser, Großküchen, Schlachtereien und in der chemischen Industrie. Flexible Verbindung von der Festleitung zum Anwendungsort. Leichtes Handling mit zuverlässigem Sperrmechanismus. Komplett aus rostfreiem Stahl, für Schlauchlängen von 10 m bis 30 m.

Schlauchaufroller VA 6000

Schlauchaufroller VA 6000

Spezialsystem für Betriebe mit hohem Hygieneanspruch und für die Produktion aggressiver Medien in der chemischen Industrie. Komplett aus rostfreiem Stahl, mit Befestigungssystem für Wand- und Bodenmontage. Schlauchlänge von 20 m bis 50 m. Auch in Hochdruck-Ausführung lieferbar.

Individual solutions

Knowing each customer’s needs is the key to fulfilling them in an optimum way. We obtain, thanks to our direct contact with partners in the downstream processing industry, a detailed view of our customers’ specific needs and requirements, which in turn allows us to integrate efficiently our deliveries into their procedures. Using this hand-in-hand principle, we contribute to our customers’ efforts to optimise their processes further.

Subassembly production / kitting-out

We are always pleased to take on the task of mounting complex subassemblies; and also of finishing, coating and putting together various different components. Our range of services also includes kitting-out (i.e. the collecting together of materials for installation purposes or in preparation for delivery). This service is also available with the option of direct delivery with specified packing. We can also supply your production line on a just-in-time basis.

Special components

As specialists in the production of drawing-based structural components, we are able to provide solutions for individual problems. Given our background of long experience with a wide range of different materials and their combinations, we can offer customer-specific solutions for all manner of requirements and applications, based on various elastomers, metals and thermoplastics.

Stamped components

When it comes to stamped-component technology, we offer the right solution for every need and application. As part of this undertaking, VIGOT can also handle foam materials, in addition to virtually all common quality-grades of rubber. Our existing plant facilities, ample stocks of raw materials and fast toolmaking capabilities allow us to react to customer desires in a flexible and timely manner.

When it comes to stamped-component technology, we offer the right solution for every need and application. As part of this undertaking, VIGOT can also handle foam materials, in addition to virtually all common quality-grades of rubber. Our existing plant facilities, ample stocks of raw materials and fast toolmaking capabilities allow us to react to customer desires in a flexible and timely manner.

Our catalogue of products includes stamped components, as well as drawing-based sealing elements such as rubber seals. The possible uses and applications are manifold, ranging from the prevention of rattling and vibrations to sealing, damping and padding, as well as noise protection or insulation.

Stamping machines

Our plant facilities include swinging-arm, bridge-type and CNC stamping machines, along with moving-beam stamping units. We use water-jet cutters or plotters to manufacture small production runs or prototypes.

Stamping tools

We can base production – depending on the material, configuration and number of parts concerned – on various types of tools, including: steel-strip cutting, combination dies, keen-edge cutting, shearing cutting, hole stamping or solid cutting.

Degrees of quality

We supply all stamped rubber components (such as those made of NR/SBR, EPDM, SBR, NBR/SBR, CR or silicon) either without self adhesive strips or with single-sided strips designed to simplify the task of installation. Our various qualities of foam product include items made of such materials as cellular polythene, cellular natural rubber, polyurethane and sponge rubber.

Profile technology

Customised solutions constitute the basis of our success. We manufacture individual profile elements in a wide range of different qualities and materials, including natural rubber, silicon, soft PVC and hard PE foam. We are particularly strong in the area of self-adhesive profiles.

Plastic profiles

Plastic can be processed in an efficient and cost-effective way. Modern types of plastic are particularly suitable when it comes to creating optimised individual solutions for a wide range of customers. This allows us to offer such items as PC profiles of modern design for covering swimming pools, window and building-frontage profiles made of high-quality ABS, transparent or tinted LED covers made of PMMA for sophisticated interior-design purposes, cover strips, angle profiles and round rods. The usage and design possibilities are almost limitless.

Profile sections made of rubber

As experienced manufacturers of rubber profiles, we supply these items in a wide range of qualities and cross-sections. The most widely used material is EPDM, which can be used to make sealing, support, joining or frame profiles, along with edge-protectors. Large production runs of rubber profile sections are required in mechanical engineering and plant construction, the automotive industry, the solar energy sector and elsewhere.

Hard-foam profiles

Hard-foam profiles offer the twin benefits of low thermal conductivity and high dimensional stability when subjected to pressure. Their areas of application include window and building-frontage construction, insulating profiles for motorhomes and edge protection in various shapes and cross-sections for the packaging industry.

Self-adhesive profile sections

We offer advanced know-how in the area of self-adhesive profile sections. These are laminated, after extrusion, with a two-sided adhesive strip. If specially developed production equipment is available, it is possible to fit virtually all common plastic, rubber and foam materials with an adhesive strip designed for permanent attachment, or merely in order to assist installation. This makes the customer’s further processing tasks considerably easier.

Special solutions

Specific product solutions are one of our main strengths. We have for example developed vacuum-lip profile sections for use in the glass industry, which have particularly proven their worth in the production of laminated panes. The small-scale deployment of these vacuum-lip profile sections often includes their use in research and development projects. This development is likewise proving its worth in the automotive sector and in the tackling of extraordinary technical challenges. Yet another of our successful innovations consists of a foam tube designed to cover and protect cable-control and actuating systems. This recyclable material furthermore complies with the EU end-of-life vehicle directives.

Moulded components

A high degree of engineering expertise, material know-how and flexibility all help us to stand out as specialists in the technical implementation of advanced ideas based on elastomers and thermoplastics. The highlights of the range are our moulded parts and drawing-based structural components, which can also be developed and deployed for one-off production as required.

Moulded rubber components

The demands placed on drawing-based moulded rubber components are as numerous as the uses to which these items are put. These include the use of these rubber products as, for example, cable conduits, buffers, bungs or end-stops. They are employed in the automotive sector as seat and armrest buffers, along with other uses, and also as bellows for Bowden cables. Our product portfolio likewise includes rubberised-metal connecting elements, such as those fitted to machine feet, bearings and sleeves, or to rails and rollers. All our solutions are developed with advanced material expertise to fit smoothly into our technologically optimised overall concepts. Our use of traditional, usually semi-automated, production techniques allows us to manufacture small batches in a cost-effective manner. If larger quantities of moulded components made of rubber and synthetic elastomers such as EPDM, NBR, silicon, CR or FPM/FKM (Viton®) are required, we can deploy our latest, fully automatic manufacturing and finishing equipment.

Moulded plastic components

The technical properties of plastics are such that they are now a thoroughly indispensable part of many areas of industrial production. VIGOT creates moulded components using a wide range of different materials, including PA, TPE, TPU, POM, ABS, PP, PC and PS. Our comprehensive experience makes us your ideal partner whenever special needs arise with regard to material, geometry or precision. We use CAD technology in our in-house toolmaking facility to create the machine tools required for customised solutions. Our range includes, along with other items, fixing clips, retainers, end-caps, handles and plastic components for headrests, along with TPE components designed to substitute moulded rubber parts in all industrial applications. .

Unsere Produkte zu Schlauchsystemen

Das gesamte Portfolio unseres Unternehmens beinhaltet neben der großen Produktauswahl auch Spezialgebiete wie z.B. Feuerschutzschläuche oder entsprechende Dienstleistungen wie die mobile Schlauchprüfung. Gemeinsam mit unserem Kooperationspartner Braunwarth Aufrollsysteme GmbH decken wir den kompletten Produktbereich für Schlauchsysteme ab. Damit bieten wir iIhnen zusätzlich zu unseren hochwertigen Produkten ein einzigartiges rundum Servicepaket. Die folgenden Links halten umfassende Informationen für Sie bereit:

Unsere Schläuche

Unsere Schläuche

Schlauchlösungen für viele Branchen von der Armatur bis zum Feuerschutzschlauch: Unser umfangreiches Sortiment sowie alle wissenswerten informationen zu unseren Schläuchen finden Sie hier.

Mehr Schläuche

Unser Auswahl im Netz

Unser Auswahl im Netz

Eine Auswahl aus der gesamten Bandbreite unserer Produkte finden Sie auch im Internet. Dort finden unsere Kunden alle wissenswerten Informationen zu unseren Produkten und können auch über unser Anfragemodul alle Angaben für ein ganz individuelles Angebot hochladen.

zum e-Katalog

Schlauchaufroller von Braunwarth

Schlauchaufroller von Braunwarth

Braunwarth steht für Qualität „made in Germany” und legt Wert auf Funktionalität, Robustheit und Langlebigkeit ihrer Produkte. Die Schlauchaufroller sind in aus hochwertigen Materialien wie Stahl und Edelstahl, für einen zuverlässigen Einsatz.

www.braunwarth-vigot.de

Safety frist- Feuerschutzschläuche

Safety frist- Feuerschutzschläuche

Sie bieten Schutz für den Funktionserhalt von Schläuchen oder Kabeln im Falle eines Brandes. Bei hohen Umgebungstemperaturen verlängern sie somit die Lebensdauer von Gummi- und Kunststoff-schläuchen oder Kabeln um ein Vielfaches und schützen somit vor frühzeitiger Alterung bzw. Ausfall.

www.fire-sleeve-f88.com

Maximall S 2000

Maximall S 2000

Der Maximall S 2000 ist flammbeständig nach GL und damit prädestiniert für Einsätze auf Schiffen aller Art und in Windkraftparks. Brennstoffe, Hydrauliköl und Schmieröl werden ebenso zuverlässig transportiert Frisch- und Seewasser, Heizungswasser, Kalt- und Warmwasser, Trinkwasser und Abwasser.

www.maximall-schlauch.de

Railway Technology

MAXIMALL® Railway Technology

Safety First - MAXIMALL® Hose Systems

VIGOT makes connections. Especially for numerous railway technology applications. The quality of the VIGOT products is supported by the Safety First safety concept. The new MAXIMALL® Hose System product range has been expanded for industry-specific applications with the railway technology segment.

With the MAXIMALL® brand and corresponding railway technology approvals, VIGOT is offering a customer-oriented selection of hoses and pre-assembled hose lines. The entire selection for railway systems was assembled in accordance with the following standards: DIN EN 45545-2, ISO 15440 and DIN EN 50553. The hose systems are suitable for R22/23 HL3.

Our selection includes hoses for a wide variety of applications, from air conditioning to heating and cooling systems to sand brakes, wheel flange lubrication and pantographs as well as suitable fittings, pipe connections and clamps. Our “Railway Technology” overview folder of MAXIMALL® Hose Systems provides you with initial information.

![]() Download Folder (DE / EN)

Download Folder (DE / EN)

Speciality Hoses for Railway Technology

We have compiled product portfolios for an initial overview of the extensive range of hoses and accessory products in cooperation with our specialist partners:

|

Railway Hose EC 190With a very tight bending radius and a broad range of possible uses, the new railway hose EC 190 supports numerous applications. The synthetic rubber hose is suitable for a temperature range from -40 °C to +125°C, is compliant with DIN EN 45545-2 and approved according to SAE 100R4.

|

|

|

Roadbed Broom HoseWith an internal diameter of 32 mm and a hardness of 70 +/- 5 shore, the hose made of natural rubber is suitable for the roadbed broom plough. The extruded version is highly abrasion-resistant and has a fabric pattern on the outside. The roadbed broom hose is supplied without an insert.

|

Roadbed

Hoses and moulded parts for cleaning the roadbed are wear parts and should meet the requirements for the train of machines. In addition to the Roadbed Broom Hose, we offer the rubber star for the roadbed as a moulded part and rubber-encased steel hoses in the following dimensions: outer diameter 30 mm, length 300 mm. Please see the enclosed datasheet for the technical data.

![]() Download data sheet, rubber star (DE)

Download data sheet, rubber star (DE)

![]() Download data sheet, rubber-encased steel hoses (DE)

Download data sheet, rubber-encased steel hoses (DE)

FlexMaster

The elastic pipe connection, which compensates for alignment differences up to max. +/- 2°, is made of steel with a galvanised surface. This elastic pipe connection is suitable for an operating pressure of 15 bar in a temperature range of -40 °C to +40 °C, for certain liquids also in higher ranges – see datasheet. The FlexMaster pipe connection is supplied in numerous lengths and diameters, as an elbow or straight pipe. Please submit your enquiry with technical data.

![]() Download data sheet Flexmaster (DE / EN)

Download data sheet Flexmaster (DE / EN)

![]() Download folder Flexmaster (DE / EN / FR / ES / IT)

Download folder Flexmaster (DE / EN / FR / ES / IT)

Continental Railway Hoses

The combination of railway hoses from our partner Conti, consistently designed to meet the high requirements of railway engineering, with fittings and accessories ensures the unproblematic use of hose lines for your company. Assembled by us in-house, inspected and certified, you receive railway hose lines that meet the DIN and EN requirements for railway engineering.

![]() Download data sheet Contitech (DE)

Download data sheet Contitech (DE)

EATON Couplings

We have been successfully partnering with EATON for more than 50 years. Since 2018, we are also an authorised specialist dealer, distributor and assembler for railway technology and railway engineering. VIGOT meets all requirements for safe hose lines with products from Aeroquip, Gromelle, Hansen, Industrial Hose, Synflex, Walterscheid and Winner – Safety First.

![]() Download Eaton main catalogue

Download Eaton main catalogue

![]() Download data sheet Eaton quick connect couplings

Download data sheet Eaton quick connect couplings

Hidden Champion: Fire Sleeve F88

Safety First – Fire Safety

The VIGOT Fire Sleeve type F88 has been the undisputed hidden champion among the VIGOT industrial engineering products for almost 50 years. This high-quality, in-house development remains convincing with outstanding fire protection properties.

MAXIMALL® Hose Systems offer a comprehensive selection of hoses according to DIN E N 45545-2, ISO 15440, DIN EN 50553. The Hose Systems conform to R22/23 HL3.

VIGOT offers the fire sleeves in the F88 SC version as extruded, silicone-coated hoses. This type is also available as F88 SC Flex, a hose with a flexible fabric construction – elastic – for long casings and as an open casing with various closure strips for subsequent installation. The coatings of the F88 SC fire protection sleeve are oil and solvent-resistant. They stand up to high mechanical stresses and exhibit good abrasion resistance. The fire sleeve has been fire protection tested and certified, among other things by Germanischer Llyod, and meets the provisions and requirements for railway engineering.

Further information about the fire sleeve is found on the separate VIGOT fire sleeve website:

Product Selection in the Electronic Catalogue

Hose Product Range – quickly accessible

A selection of hoses from our standard product range is available in our electronic catalogue. Roll length enquiries are uncomplicated, with no commitment. Drawings and files can be uploaded for special requests. Datasheets for the respective hose can be printed from the electronic catalogue. Naturally we also supply other hoses and diameters on request. Allow us to advise you in detail. We will be happy to call you back!

Fire-sleeves:

Safety first

VIGOT fire-sleeves are made of a specially impregnated, mineral-based carrier material. This heat protection fabric presents no health risk and fulfils the requirements of the health regulations to a high degree.

www.fire-sleeve-f88.com

Our portfolio online

You can also find a section from the whole range of our products on the Internet. This link takes you to our new e-catalogue. Here our customers will find all the useful information about our products and can also use our request module to upload all the details for a customised quotation. Go to the e-catalogue

SCHAUENBURG Industrietechnik

As a system supplier, we are a reliable partner to industry for technically convincing product solutions. One Stop Solution is the principle after we accompany projects from development to series production in many important industries. In doing so, we operate successfully on the national and international market. Read more...